Modbus TCP Direct

1. Functional Overview

ThingsPanel's Modbus TCP access service supports direct connection to industrial devices, automatically collecting data and reporting to the platform. Key features:

- Visual Configuration: Web interface to configure device parameters and data address tables.

- Smart Polling: Flexible data collection strategies and cycle configuration.

- Device Control: Supports writing to coils and registers for control.

- Connection Management: Automatic reconnection, connection pool management, status monitoring.

2. Quick Start

Prerequisite: Modbus TCP connectivity service is deployed and registered to the platform.

2.1 Prepare Device Information

Collect the following device information before configuration:

| Parameter | Description | Example |

|---|---|---|

| IP Address | Device IP Address | 192.168.1.100 |

| Port | Modbus TCP Port | 502 |

| Slave ID | Device SlaveID | 1 |

| Data Address | Register Address Range | 40001-40010 |

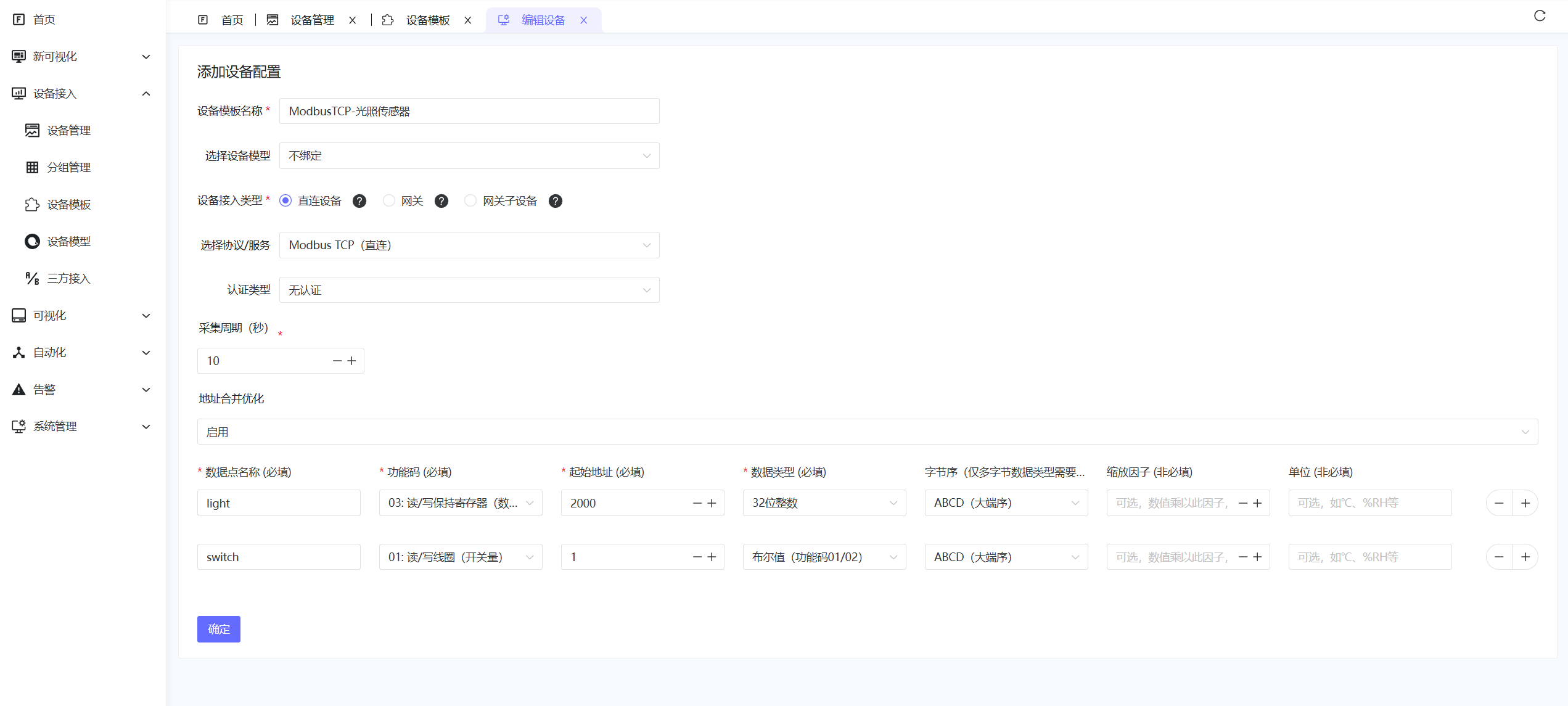

2.2 Create Device Template

- Go to Device Connectivity - Device Templates.

- Select Access Type: Direct Device.

- Select Modbus TCP (Direct), set Authentication Type to None.

- Fill in Collection Interval, enable Address Merge Optimization if needed.

- Configure Collection Parameters as follows:

| Config Data | Description | Example |

|---|---|---|

| Data Point Name | Unique Identifier | temperature |

| Function Code | Modbus Function Code | 03 (Read Holding Registers) |

| Start Address | Register Address | 40001 |

| Data Type | Data Parsing Type | Float32 |

| Endianness | Big/Little Endian | Big Endian |

| Scaling Factor | Optional, Value Scaling | 0.1 |

| Unit | Optional | °C |

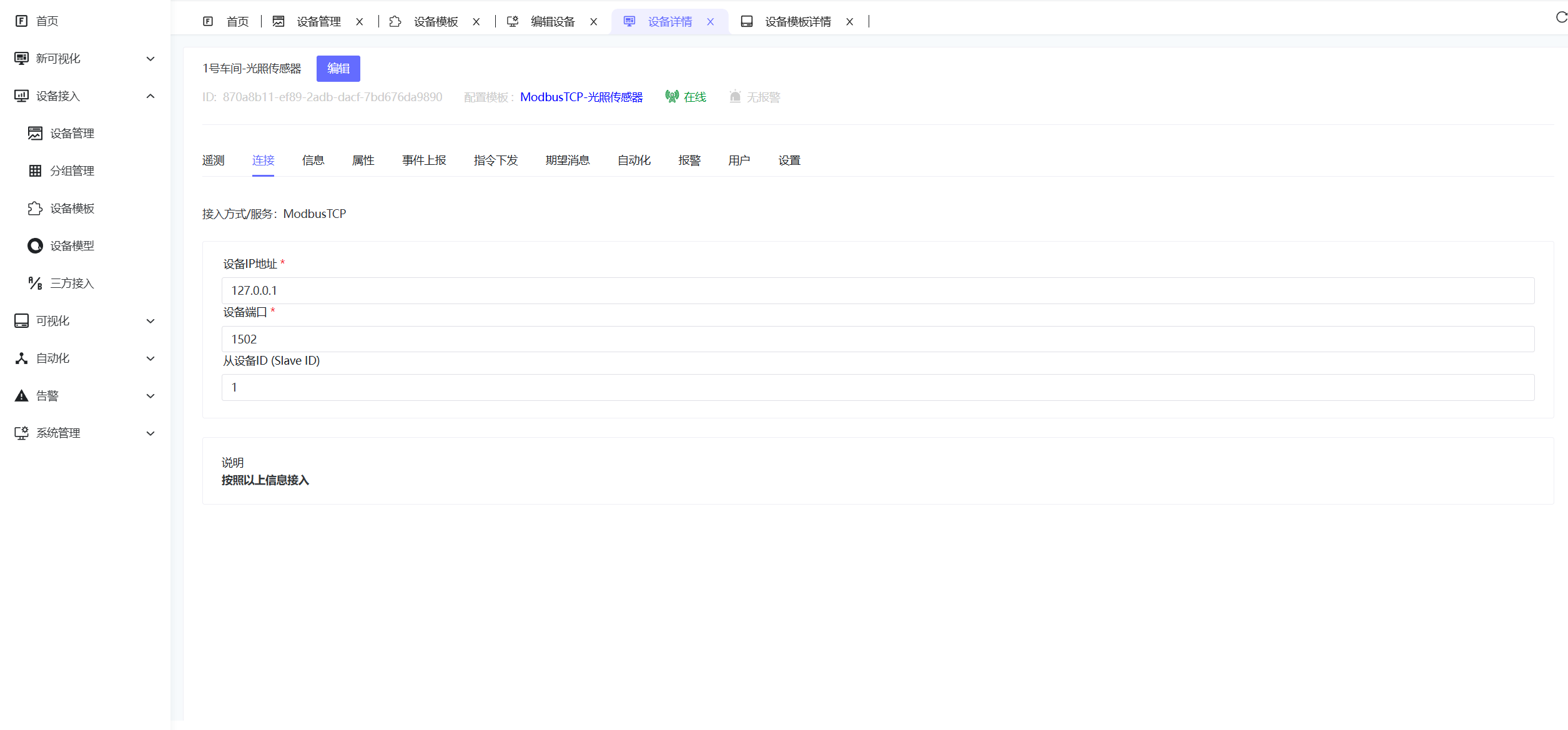

2.3 Create Device

- Go to Device Connectivity - Device Management → Add Device.

- Fill in device name, select device type: The device template created in the previous step.

- Enter Device Details, select the Connection tab, fill in Device IP, Port, Slave ID, and Save.

Device IP: 192.168.1.100

Port: 502

Slave ID: 1

3. Data Address Table Configuration

3.1 Add Data Points

Click Data Address Table → Add Data Point to configure parameters:

| Config Item | Description | Example |

|---|---|---|

| Data Point Name | Unique Identifier | temperature |

| Function Code | Modbus Function Code | 03 (Read Holding Register) |

| Start Address | Register Address | 40001 |

| Data Length | Register Quantity | 2 |

| Data Type | Data Parsing Type | Float32 |

| Endianness | Big/Little Endian | Big Endian |

| Scaling Factor | Value Scaling | 0.1 |

3.2 Supported Function Codes

| Function Code | Description | Address Range |

|---|---|---|

| 01/05 | Read/Write Coil Status | 00001-09999 |

| 02 | Read Discrete Input | 10001-19999 |

| 03/06 | Read/Write Holding Register | 40001-49999 |

| 04 | Read Input Register | 30001-39999 |

3.3 Data Types

| Type | Registers Occupied | Description |

|---|---|---|

| Bool | 1 | Boolean |

| Int16 | 1 | 16-bit Signed Integer |

| UInt16 | 1 | 16-bit Unsigned Integer |

| Int32 | 2 | 32-bit Signed Integer |

| UInt32 | 2 | 32-bit Unsigned Integer |

| Float32 | 2 | 32-bit Float |

| Float64 | 4 | 64-bit Float |

4. Device Control

4.1 Supported Control Types

- Coil Control: Function Code 05 (Single Coil)

- Register Control: Function Code 06 (Single Register), 16 (Multiple Registers)

4.2 Control Operations

Real-time control can be performed from the platform by sending control commands using the configured data point names:

{

"temperature": 15.2,

"switch": 1,

"speed": 1200

}

Explanation:

temperature: Set target temperature valueswitch: Control switch state (0=OFF, 1=ON)

5. Troubleshooting

5.1 Common Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Device Disconnected | Network unreachable, IP error | Check network, confirm device IP |

| Read Fail | Address error, unsupported function code | Check register address and function code |

| Data Abnormal | Data type error, endianness error | Confirm data type and endianness |

| Control Fail | Device read-only, permission denied | Check write permission and function code support |

5.2 Debugging Suggestions

- Step-by-step: Configure a few data points first, then add more.

- Tools: Use Modbus tools to verify communication.

- Logs: Check system logs for detailed errors.

- Network: Use ping to test connectivity.

6. Performance Optimization

6.1 Address Merge Optimization

Enable address merge optimization to improve efficiency:

- Continuous Addresses: System automatically merges continuous register addresses.

- Reduce Requests: Reduces Modbus request count, improving response speed.

- Suggestion: Configure related data points in continuous address ranges.

6.2 Collection Cycle Setting

Set appropriate collection cycles:

- High Frequency: Important parameters (1-5s).

- Normal: General parameters (10-30s).

- Status: Slowly changing parameters (60s+).